Variation Reduction Kaizen (VRK): Statistical problem solving and process control in a 5-day kaizen format. Use VRK while executing your kaizen road map when a more sophisticated & comprehensive "green belt or black belt" project is not necessary. Transactional Process Improvement (TPI): Lean tools adapted to transactional/support function process improvements in a 3-5 day kaizen format. DO NOT underestimate the untapped value of these improvements!

Single Minute Exchange of Dies (SMED): A process for reducing the amount of time it takes to changeover a machine or process. Measured from the last good piece of the previous product to the first good piece of the next product.

Production Preparation Process (3P): A lean method, offered in a five day kaizen format, for designing products and processes that better meet customer's needs. A critical element of any New Product Development and Launch processes. Meet targeted safety, quality, delivery (lead time) and cost levels more consistently. Modules available are:

- Co ordination with purchaser for getting the offer from vendor.

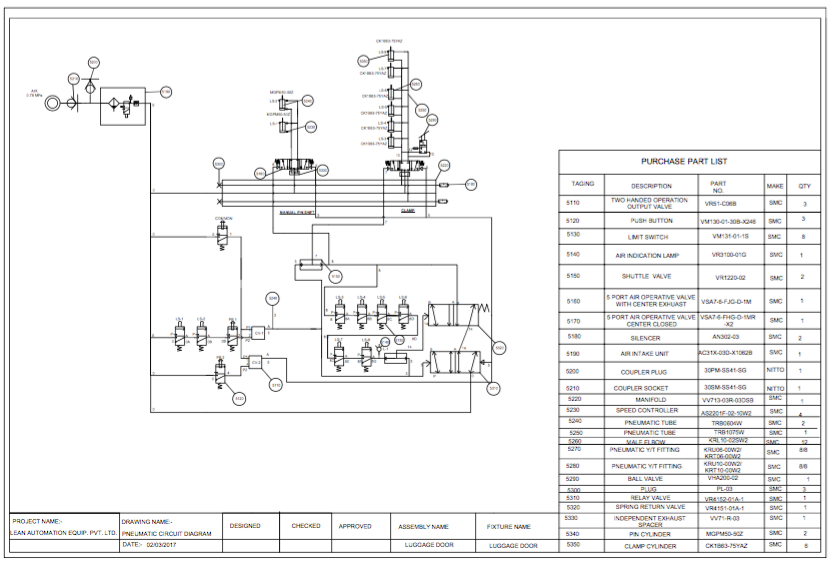

- Sizing & Selection of various field instruments.

- Technical evaluation of offer & discussion with the vendor.

- Evaluation of drawing & QAP of instruments.

- Preparation of Project Deliverable like Instrument Data sheet, Cable & JB Schedule, Cable Tray Routine Drawings,

- Preparation of Instrument Hook-up Drawings & BOM for Erection Material.

- Preparation of Bill of Material for Piping Activities & Erection Hardware

- Assist project manager for getting dispatch clearance from customer.

- Supervision of fabrication & installation activities of skid, field instruments etc.

- Assist project manager for audit conducted by quality department of company.

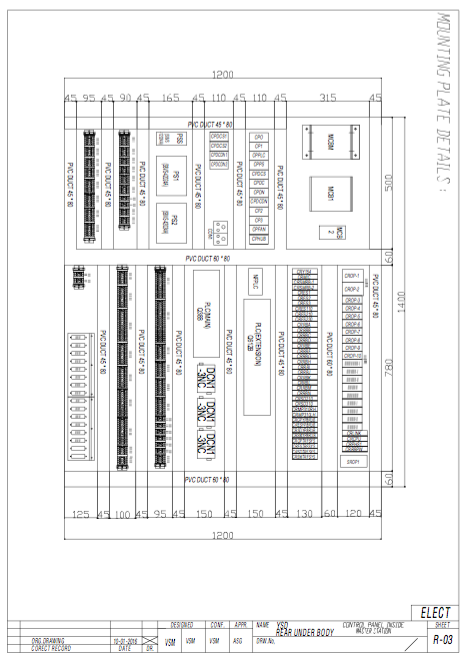

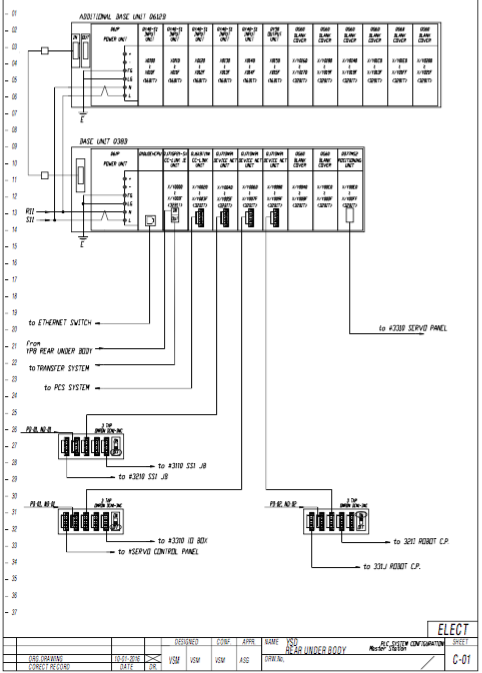

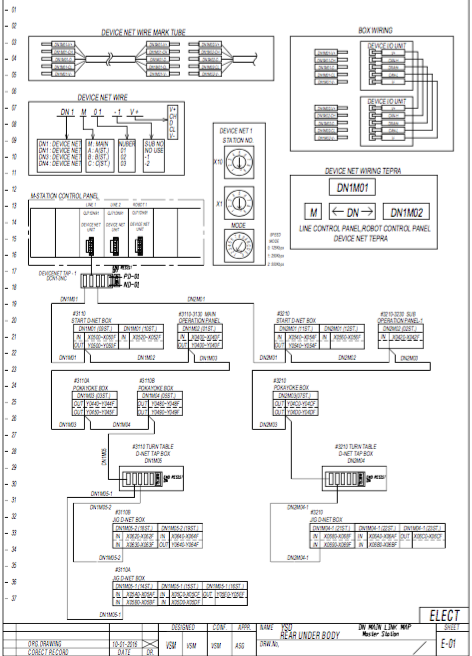

- Preparation for the Electrical Control Panel & Field wiring diagram with Eplan software.

- Preparation of Project Deliverables like Instrument Datasheet, Cable & JB Schedule, Cable Tray Routine Drawings.

- Preparation of Bill of Material for Project Activities & Commissioning Hardware.

- Taking data from Mechanical design & Planning for the Plan Layout.

- Inspection of Control Panel & Panel boxes at Vendor end.

- Installation & Commissioning of various Control instruments & units at site.

- Interfacing & Proving of I/Os with ROBOT & PLC.

- Troubleshooting & resolving issues during Auto Cycles

- Releasing PRs as per required material.

- Heading a team for installation, commissioning & other Controls related activities.

- Keeping Update of Document Exchange Control Register.

Automation

Utilisation of leans tools to operate the entire work flow, we make use of folowinf principle while automating a process

5S/Visual Management: A place for everything & everything in its' place! It's NOT just about housekeeping. It's about achieving the Safety, Quality, Delivery, & Cost benefits of a visually managed workplace.

Standard Work: Design and implement cells/processes to TAKT time (Total Daily Operating Time/Total Daily Requirements). Produce only what's needed, when it is needed, based on customer demand…the same way, every time.

Sales & Operations Planning (S&OP): Aligning commercia style="padding: 2em;"l and operational teams with respect to understanding and managing demand with the intention of providing 100% on-time delivery to customer request, utilizing minimal human and working capital. Material Pull Systems & Kanban: Downstream processes pull from upstream processes only the amount of goods that are needed, when they are needed. Typically employing a pull signal (kanban) to the upstream supplier as to what supply is needed to meet demand.

- Concept 3P

- Design 3P

- Process 3P

- Plant Layout 3P

Total Productive Maintenance (TPM): A process designed to completely eliminate unplanned downtime in the manufacturing process thus improving the predictability of safety, quality, delivery and productivity performance.

Root Cause Problem Solving : Get to true root cause(s) of problems through basic, practical problem solving techniques. Utilize lean/sigma tools to resolve and control to prevent recurrence.

- Taking handing over of Project from Sales & Marketing team to the projects department.

- Identify the scope of work by evaluating Tender Document.

- Preparation of Instrument Index & Review of Process Data.

- Preparation of input query log.

- Preparation of Project Schedule in co ordination with project Manger.

- Make a DAP meeting with customer. Resolve the queries by discussion.

- Preparation of Technical Specification Sheet for floating the enquiry.

- Co ordination with purchaser for getting the offer from vendor.

- Sizing & Selection of various field instruments.

- Technical evaluation of offer & discussion with the vendor.

- Evaluation of drawing & QAP of instruments.

- Preparation of Project Deliverable like Instrument Data sheet, Cable & JB Schedule, Cable Tray Routine Drawings,

- Preparation of Instrument Hook-up Drawings & BOM for Erection Material.

- Preparation of Instrument Hook-up Drawings & BOM for Erection Material.

- Preparation of Bill of Material for Piping Activities & Erection Hardware

- Assist project manager for getting dispatch clearance from customer.

- Supervision of fabrication & installation activities of skid, field instruments etc.

- Assist project manager for audit conducted by quality department of company.

- Keeping Update of Document Exchange Control Register.

- Complete electrical installation, engineering, HMI and PLC application software development, servicing and training, and commissioning of customers support.

- Initiated several concurrent projects for different applications, responsible for coordination, timely development, production functioning and smooth implementation of automation systems.

- Providing technical reports and documentation, according to company standards.