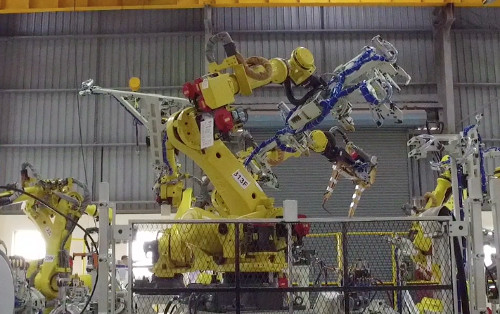

Expertise related to Process Planning, Layout including Robot reach studies, Simulation & Offline programming which plays a crucial role in Robotic Lines is available under one roof at Lean Automation. As is Selection of Robotic Weld guns and defining the parameters required according to panel thickness Robot Programming, Zoning and Safe Robot functions. We also provide complete Automation through PLCs including PLC programming and controlling multi-model multi-variant Lines.